At $23.7 Billion and a market growth approaching 35%, it is difficult to deny the compelling attributes associated with online training. Occupational health and safety training delivered online is especially compelling because of the level of compliance-assurance that can be attained, as well as the significant ROI that so many companies have experienced. In pursuing these benefits however, many organizations have unfortunately, experienced less than what was expected. The problem is that along with the growth of demand, the number of providers of online occupational health and safety training has increased as well. To ensure your organization realizes the potential benefits it’s important to ask the right questions that identify online occupational health and safety providers that provide the training content that will meet expectations.

How expert are the subject matter experts?

How expert are the subject matter experts?

What are the credentials of the authors of your online safety training? Make sure the subject matter experts, are in fact, experts in the occupational health and safety subject. Not only should they have significant experience in the subject, they should be board certified, and hold advanced degrees in a field relevant to that subject matter. Look for individual credentials, but also, look at the level of complexity and scope of the provider company’s project history. The subject matter experts must be involved in the safety training development process from defining the required competencies to final quality assurance.What is the instructional design approach?

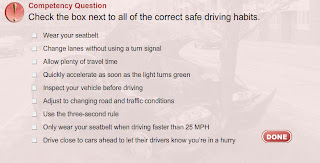

Just because they know the material, doesn’t mean they can teach it. The body of instructional systems design and adult learning theory has evolved over the years and you want to be sure that the safety training content you deploy takes full advantage of the design strategies availableWhat is the content’s interactivity and media-complexity level?

Probably the most conspicuous differentiator in quality and cost between online occupational health and safety providers is level of interactivity and media complexity. Some online occupational health and safety training providers offer content that is little more than web-based PowerPoint slides, or aging safety training videos streamed online. Look for online safety training providers who leverage the technologies available in the web 2.0 of today, such as dynamic, variable, non-linear navigation based on learner input and intensive action scripting. Also look for content that is engaging by making full use of non-static avatars; 3-D animations and simulations; and studio-produced audio.

Probably the most conspicuous differentiator in quality and cost between online occupational health and safety providers is level of interactivity and media complexity. Some online occupational health and safety training providers offer content that is little more than web-based PowerPoint slides, or aging safety training videos streamed online. Look for online safety training providers who leverage the technologies available in the web 2.0 of today, such as dynamic, variable, non-linear navigation based on learner input and intensive action scripting. Also look for content that is engaging by making full use of non-static avatars; 3-D animations and simulations; and studio-produced audio.